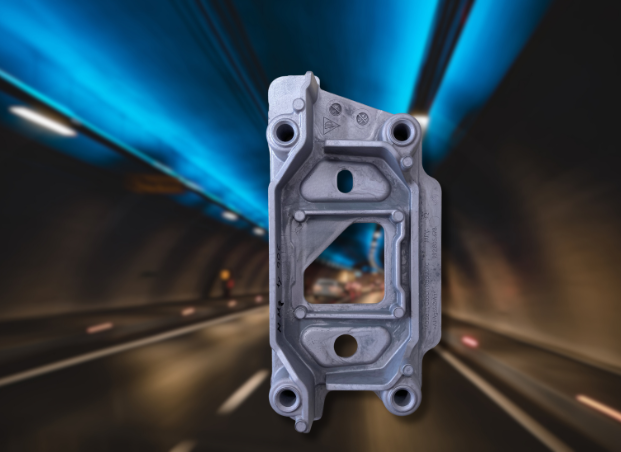

Automotive: Impact Absorber Components

In the competitive sphere of the automotive industry, innovation is key to staying ahead. That's precisely what was achieved with a breakthrough in impact absorber components.

By embracing both 3D printing and die-casting techniques, the same alloy was utilized to produce a series that not only matched but exceeded industry standards. The introduction of AlMgty® alloy marked a turning point. This material's exceptional combination of strength and ductility led to an impressive 21% weight reduction—a significant leap forward in design and efficiency. And the complete weight-saving potential was not yet fully determined.

Simultaneously, the component maintained high strength, ensuring safety was not compromised for the sake of weight savings. This dual approach to manufacturing not only streamlined the production process but also showcased the potential of hybrid manufacturing techniques, with AlMgty® providing almost identical strength properties, no matter if processed in high-pressure die casting (HPDC) or laser powder bed fusion (LDBF).

The result? A more fuel-efficient, performance-optimized vehicle that resonated with eco-conscious consumers.

Tailored Solution Automotive: Hybrid Manufacturing

USE CASE: IMPACT ABSORBER COMPONENTS

In a world where automotive design demands efficiency and sustainability, hybrid manufacturing can make you stand out. A successful case combined 3D printing with high-pressure die casting, utilizing the same AlMgty® alloy to produce impact absorber components.

CHALLENGE: WEIGHT REDUCTION AND SUSTAINABILITY

The company from the automotive industry regocnized the need for lighter vehicles to improve fuel efficiency and environmental impact without sacrificing performance or safety.

SOLUTION: AlMgty® & HYBRID MANUFACTURING

The result was a performance-optimized vehicle that appealed to eco-conscious consumers. The vehicle's lighter weight led to increased fuel efficiency, while the manufacturing process streamlined production. This breakthrough has marked a turning point for the automotive industry, setting new standards in design, sustainability, and safety.